Speedy 3D Printers: Transforming DIY and Small - Scale Manufacturing at Home

In the realm of home - based innovation, speedy 3D printers have emerged as a transformative force, reshaping how Western consumers aged 20 - 40 approach DIY projects and small - scale manufacturing. No longer confined to slow, niche hobbyist tools, modern high - speed 3D printers blend efficiency with accessibility, turning once - time - consuming creation processes into streamlined, accessible endeavors. For tech - curious makers, entrepreneurs, and even casual DIY enthusiasts, these devices are unlocking new possibilities—from prototyping custom gadgets to producing functional household items—all within the comfort of their homes.

Breaking the Speed Barrier: From Hours to Minutes

The most defining advancement of today’s speedy 3D printers is their ability to drastically cut down print times. Traditional 3D printers often required 8 - 12 hours to produce a simple object like a phone stand; now, leading models such as the Bambu Lab X1 Carbon can complete the same task in under 45 minutes. This leap is driven by innovations like high - torque stepper motors, which enable faster movement of print heads, and advanced slicing software that optimizes layer deposition without sacrificing precision. For example, Prusa’s MK4 printer uses a “Speedy Mode” that boosts print speeds by 200% compared to its predecessor, while maintaining a layer resolution of 0.1mm—critical for ensuring detailed, usable outputs. This speed shift is a game - changer for small - scale manufacturers: a independent jewelry designer, for instance, can now prototype 5 - 6 custom pendants in a single day, accelerating their path from concept to market.

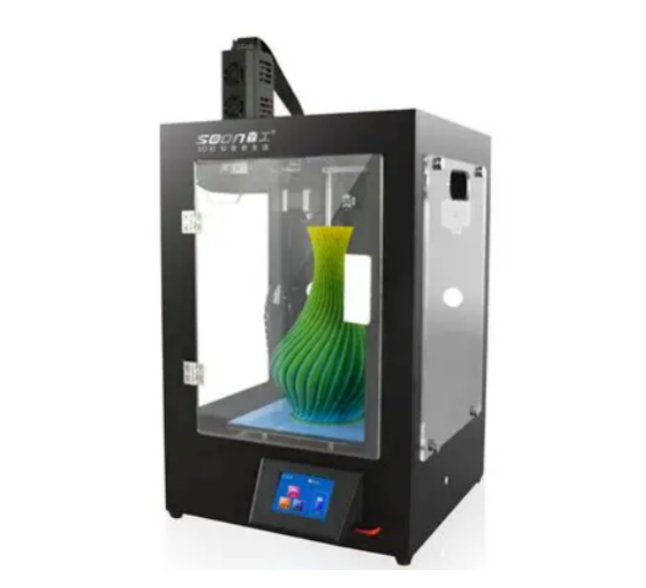

Expanding Material Versatility: Beyond Plastic

Speedy 3D printers are not just fast—they are also more versatile in handling materials, a key factor for both DIYers and home manufacturers. While early models were limited to basic PLA plastic, modern high - speed printers can work with durable ABS, flexible TPU, and even specialized filaments like carbon - fiber reinforced PETG. The Ultimaker S7, for example, supports over 300 different materials, including heat - resistant options ideal for creating replacement parts for small appliances. This versatility empowers users: a DIY enthusiast can 3D print a custom silicone - like grip for their tools, while a home - based toy maker can produce child - safe, BPA - free figurines. For Western consumers prioritizing sustainability, many speedy printers also work with recycled filaments, aligning with the 20 - 40 age group’s growing focus on eco - friendly practices.

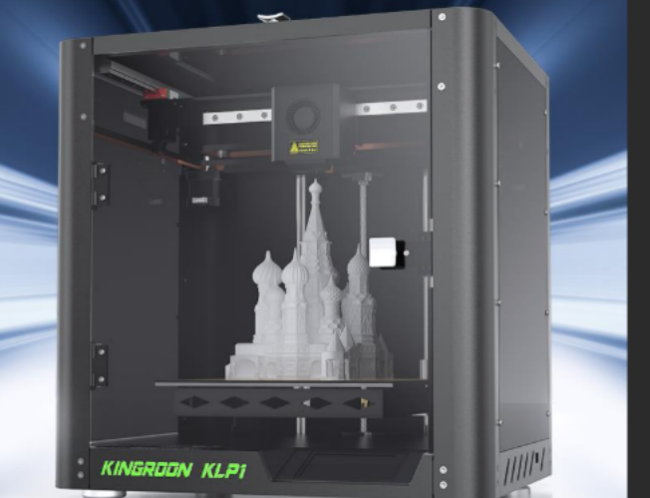

User - Friendly Innovation: Democratizing Manufacturing

Accessibility has been a major hurdle for 3D printing adoption—and speedy models are addressing this head - on. Modern printers feature intuitive touchscreen interfaces, automated bed leveling (which eliminates the need for manual calibration), and Wi - Fi connectivity for remote monitoring. The Anycubic Kobra 2, for instance, uses AI - powered error detection to pause prints if a filament jam occurs, reducing wasted time and materials. Many also come with pre - loaded print templates, allowing beginners to start creating immediately—whether it’s a custom cable organizer or a prototype for a new tech accessory. This user - friendliness is critical: it means a graphic designer with no prior 3D printing experience can now turn their digital designs into physical products, or a small business owner can produce low - volume inventory without investing in expensive industrial equipment.

Shaping the Future of Home Production

For the 20 - 40 age group in Western countries—many of whom value customization, flexibility, and self - sufficiency—speedy 3D printers are more than just tools; they are enablers of creativity and entrepreneurship. A freelance product designer can now test prototypes at home without outsourcing, cutting costs and speeding up iterations. A family can 3D print replacement parts for broken furniture instead of buying new items, reducing waste. Even hobbyists are pushing boundaries: some are using high - speed printers to create custom cosplay armor pieces, while others are experimenting with small - batch production of handmade candles with 3D - printed molds.

In conclusion, speedy 3D printers are revolutionizing home - based DIY and small - scale manufacturing. By combining speed, material versatility, and user - friendliness, they are democratizing access to production tools that were once out of reach. For Western consumers aged 20 - 40, this means turning creative ideas into tangible products faster, more affordably, and more sustainably than ever before—heralding a new era of home - grown innovation.

(Writer:Frid)