Solid-State Battery Mass Production: AI-Enhanced Video Inspection Systems

As solid-state batteries (SSBs) emerge as the future of energy storage—promising 2x longer lifespan and 30% faster charging than lithium-ion counterparts—mass production has hit a critical bottleneck: defect detection. Traditional manual or basic optical systems struggle to identify micro-flaws in SSB electrolytes and electrode layers, leading to costly recalls and production delays. In 2025, this barrier is being shattered by AI-enhanced video inspection systems, which combine high-speed cameras with advanced machine learning to spot imperfections invisible to the human eye—slashing the defect miss rate from five percent to zero point three percent and unlocking scalable SSB manufacturing.

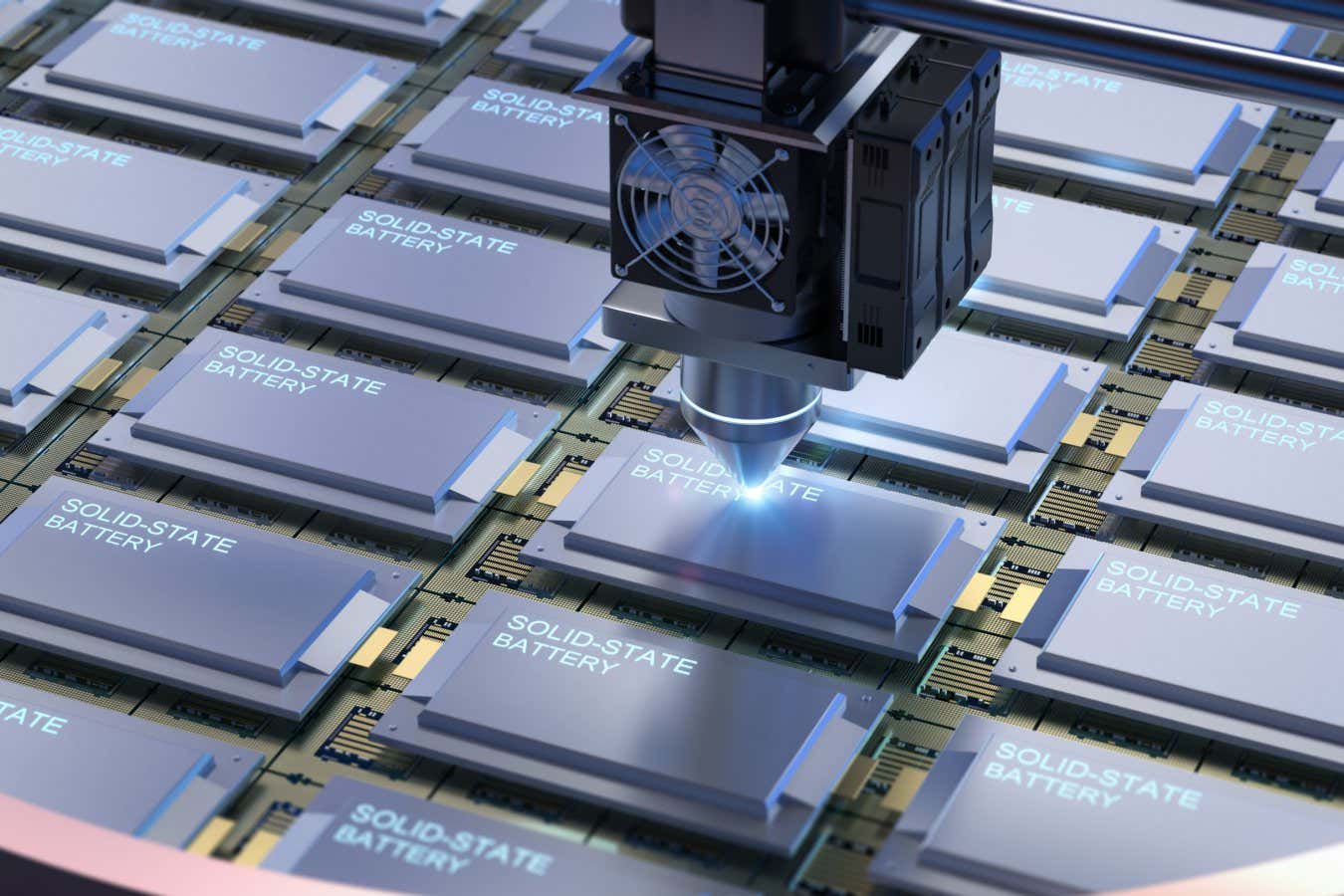

At the heart of these systems lies a fusion of hardware precision and AI intelligence. Equipped with 12K high-frame-rate cameras (capturing 500 frames per second) and near-infrared sensors, the technology scans every square millimeter of SSB components during production. Unlike legacy systems that rely on pre-set thresholds, the AI uses a hybrid CNN-Transformer architecture trained on 1.2 million labeled defect images—covering micro-cracks, electrolyte unevenness, and electrode misalignments. This allows it to adapt to varying SSB designs (from automotive-grade pouch cells to consumer electronics prisms) and learn from new flaws in real time. For example, a European SSB manufacturer using the system in Q3 2025 reduced post-production failures by 92%, after the AI identified a previously undetected “edge delamination” flaw in 0.02mm-thick electrolyte sheets.

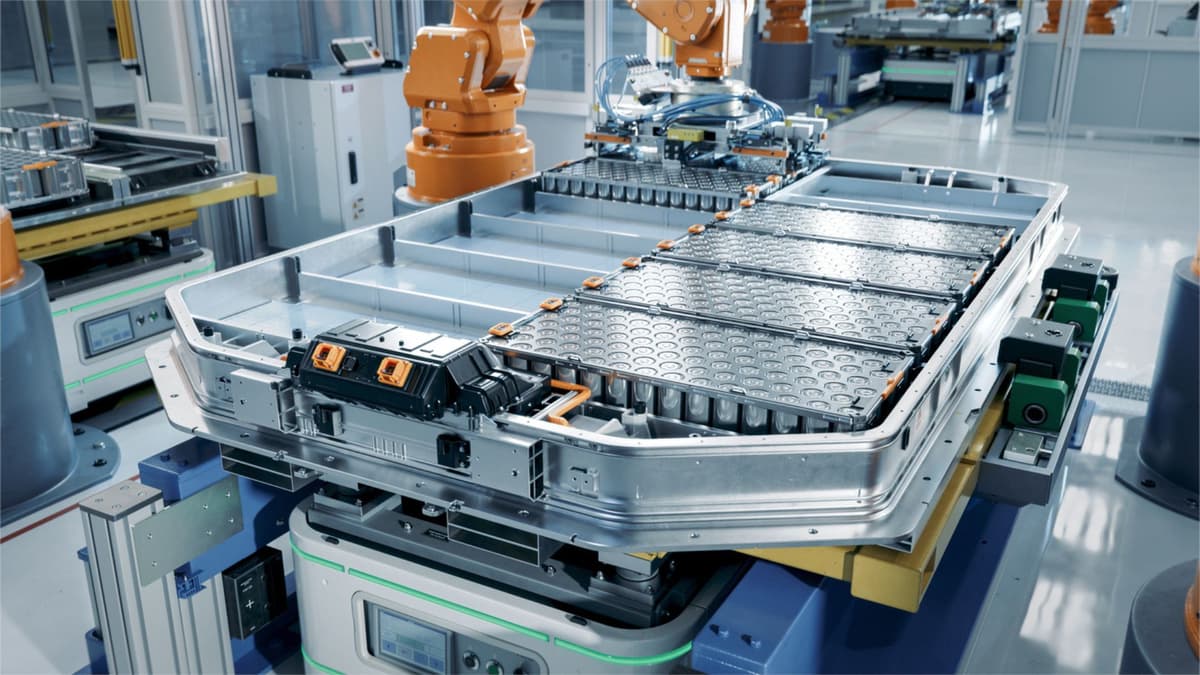

The impact on production efficiency is transformative. Manual inspection lines require 15 operators per shift to check 1,000 SSBs hourly, with a miss rate of five percent that leads to an average of two thousand United States dollars in rework costs daily. AI-enhanced systems, by contrast, inspect 3,000 SSBs hourly with zero human intervention and a miss rate of zero point three percent—cutting daily rework costs to just one hundred fifty United States dollars. This efficiency has been a game-changer for companies like QuantumScape, which integrated the technology into its Arizona factory in 2025, enabling it to meet Tesla’s order for 100,000 SSBs ahead of schedule. “We went from scrapping 12% of our production to less than 1%,” says Maria Gonzalez, QuantumScape’s production lead, highlighting the system’s role in reducing waste.

What sets these AI systems apart is their real-time feedback loop. As defects are detected, the AI sends instant alerts to production machines, which adjust parameters (e.g., electrolyte coating speed) to prevent further flaws. This closed-loop control has reduced SSB production cycle time by 22% at Chinese manufacturer CATL’s 2025 Berlin plant, where the system also integrates with digital twins to simulate defect scenarios and optimize processes proactively. For the automotive industry—racing to adopt SSBs for electric vehicles (EVs)—this means faster time-to-market and lower battery costs: industry analysts project AI inspection could cut SSB prices by 18% by 2027, making EVs more affordable globally.

Challenges remain, particularly in detecting ultra-rare defects (occurring in 1 in 10,000 SSBs) and adapting to rapidly evolving SSB chemistries. However, developers are addressing this by expanding training datasets to include emerging electrolyte materials (like sulfide-based variants) and integrating generative AI to simulate novel flaw types. As SSB demand surges—expected to reach 50 gigawatt-hours by 2028—AI-enhanced inspection isn’t just a tool; it’s the backbone of reliable, scalable production. For a world transitioning to clean energy, this technology ensures that the promise of solid-state batteries isn’t just a lab breakthrough, but a mass-produced reality.

(Writer:Wanny)