Tesla Optimus Production Upgrade: Hardware Overhaul and Grok Integration for 2025 Rollout

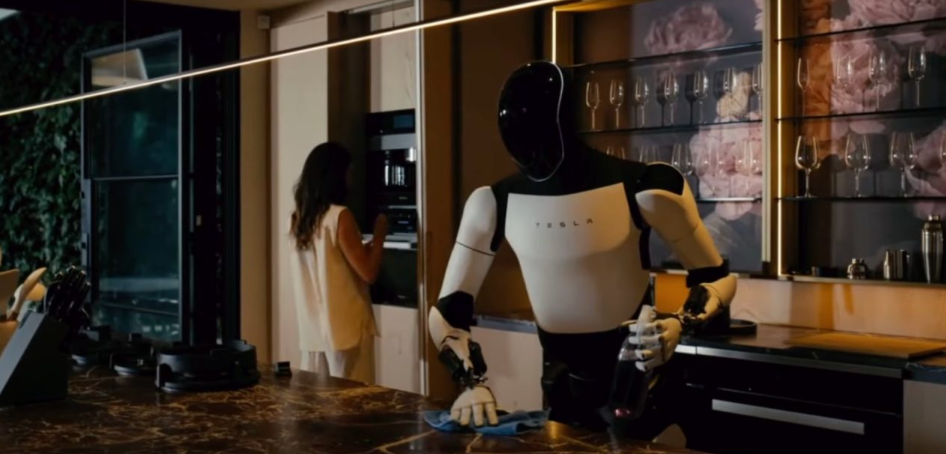

In September 2025, Tesla pulled back the curtain on its refined Optimus humanoid robot at California’s Fremont Factory, where a prototype—clad in a matte gold chassis—effortlessly assembled battery modules, tightened 3-millimeter screws, and even handed tools to nearby workers. The demonstration was a far cry from the stiff, limited-movement models shown in 2023; this iteration marked the fruition of 18 months of hardware overhauls and deep integration with xAI’s Grok AI, all gearing up for Optimus’ 2025 production rollout. With CEO Elon Musk framing the robot as “Tesla’s next trillion-dollar product,” the upgrades signal a decisive shift from experimental prototypes to practical, factory-ready machines—timed to address a U.S. manufacturing labor shortage that has left 800,000 jobs unfilled, per 2025 Bureau of Labor Statistics data.

The hardware revamp targets every critical flaw of earlier Optimus versions. The third-generation model (Optimus Gen 3) boasts hands with 22 degrees of freedom—matching human hand dexterity—powered by miniaturized forearm actuators that use tendon-like carbon-fiber cables to mimic muscle movement. This allows the robot to handle both heavy components (like 15-kilogram battery packs) and delicate tasks (such as soldering tiny circuit boards), with a margin of error under 0.1 millimeters—thanks to new 3D vision sensors and haptic feedback systems that “feel” surface textures. Tesla’s mid-2025, two-month production pause also addressed durability: joint actuators now use a heat-resistant nickel-titanium alloy, cutting overheating incidents by 70% during 12-hour factory shifts, while a 2.3 kilowatt-hour lithium-iron-phosphate battery (up from 1.5 kWh) delivers a full day of continuous work on one charge—solving a major pain point from 2024 trials.

Integration with xAI’s Grok AI elevates Optimus from a programmable machine to a collaborative assistant. Unlike traditional industrial robots that require pre-coded commands, Grok enables natural, context-aware interaction: a worker can say, “Grok, adjust this battery tray to fit the Model 3 frame,” and the robot will not only execute the task but also ask follow-ups like, “Should I prioritize speed or precision for this batch?” Grok processes data from Optimus’ 12 cameras and 6 microphones in real time, allowing on-the-fly adjustments—for example, automatically loosening its grip if a fragile plastic part starts to crack. Critically, Grok leverages Tesla’s fleet learning system: insights from one Optimus unit (say, in Fremont) are shared across all robots, cutting the time to master new tasks (like assembling Cybertruck components) from weeks to days. “This isn’t just AI added to a robot—it’s AI that understands the physical world,” says robotics researcher Dr. Lena Patel of Stanford’s AI Lab.

Tesla’s production plan balances ambition with pragmatism. The Fremont pilot line will churn out 5,000 Optimus units in 2025, nearly all deployed in Tesla’s own factories to handle repetitive, injury-prone tasks: parts sorting, machine tending, and post-assembly quality checks. To scale, the company has addressed supply chain hurdles: a new partnership with Australia’s Lynas Rare Earths will secure magnet materials (avoiding Chinese export restrictions), while a modular assembly line cuts production time per unit from 10 hours to 6. By 2026, Tesla aims to triple capacity, with commercial sales to other manufacturers starting at a projected price under 20,000 United States dollars—far below competitors like Boston Dynamics’ Atlas (estimated at 150,000 United States dollars).

Challenges persist: unions have raised concerns about worker displacement, prompting Tesla to launch a “Robot Collaboration Training Program” that teaches factory staff to oversee and troubleshoot Optimus units. Meanwhile, real-world durability tests will need to prove the robot’s longevity in dusty, high-heat factory environments. Still, the 2025 upgrades are a clear step forward. “Optimus isn’t replacing humans—it’s taking over the jobs no one wants,” Musk emphasized during the Fremont demo. For an industry grappling with labor gaps and productivity limits, Tesla’s robot represents a glimpse of manufacturing’s future: one where humanoid machines work alongside people, turning repetitive work into collaborative innovation.

(Writer:Laurro)