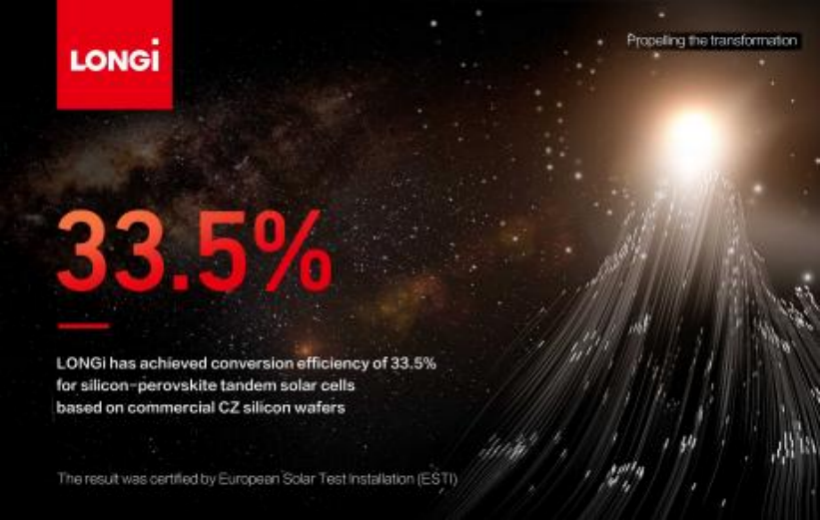

Perovskite Solar Race 2025: SolaEon's 31.38% vs LONGi's 33% Tandem Cell Breakthrough

2025 has solidified its status as a transformative year for perovskite solar technology, with two industry leaders—Europe’s SolaEon and China’s LONGi—unveiling efficiency records that rewrite the rules of renewable energy. In April 2025, SolaEon, a startup backed by research partnerships with Switzerland’s Swiss Federal Institute of Technology Zurich (ETH Zurich) and Germany’s Fraunhofer Institute, announced its all-perovskite tandem cell had achieved 31.38% conversion efficiency, independently verified by the International Electrotechnical Commission (IEC). This marked a 2% jump from its 29.34% record in late 2024, a pace of improvement that outstrips traditional silicon cell development by nearly three times. Just two months later, at the June 2025 SNEC International Solar Energy Conference in Shanghai, LONGi—one of the world’s largest solar manufacturers—stunned the industry with a crystalline silicon-perovskite tandem cell hitting 33% efficiency, certified by the U.S. National Renewable Energy Laboratory (NREL). These figures shatter the long-standing efficiency ceiling of single-junction silicon cells, which rarely exceed 27%, and bring commercial perovskite technology closer to mainstream adoption.

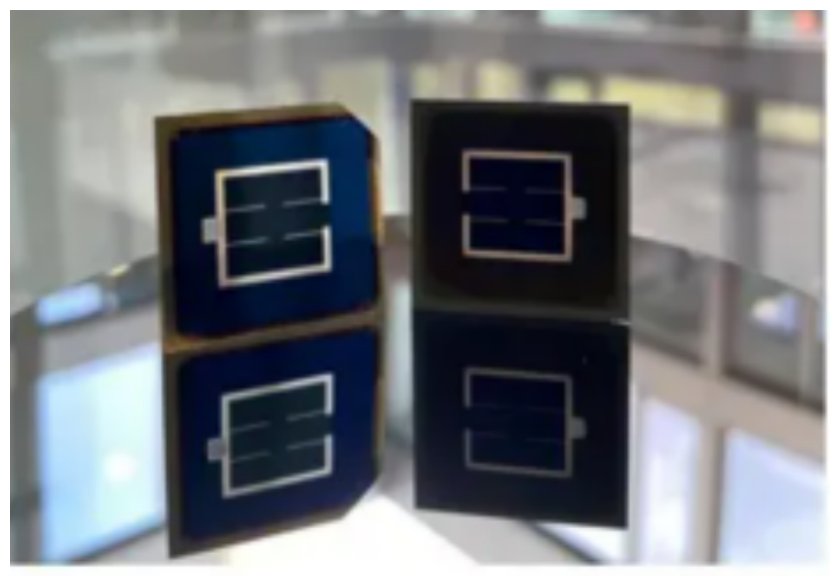

The technical strategies behind these milestones reflect contrasting but equally impactful approaches. LONGi’s 33% cell uses a “tandem stack” design: a top layer of cesium-formamidinium-lead triiodide perovskite absorbs high-energy blue and violet light, while a bottom layer of monocrystalline silicon captures lower-energy red and infrared wavelengths. This combination minimizes “thermalization loss”—the waste of energy when photons carry more power than a cell can convert—an issue that has plagued single-material solar technology for decades. Critically, LONGi’s cell measures 260.9 cm², a size that aligns with standard commercial solar modules, unlike the tiny lab-scale prototypes common in early perovskite research. “We didn’t just chase a number—we built a cell that fits into existing manufacturing lines,” explained Dr. Li Jiawei, head of LONGi’s Advanced Solar Technology Division, noting that the design requires only minor tweaks to the company’s current silicon cell production facilities, reducing scaling costs by an estimated 15%.

SolaEon’s all-perovskite tandem, by contrast, eliminates silicon entirely, stacking two layers of perovskite with different bandgaps (1.8 eV and 1.2 eV) to capture a broader spectrum of sunlight. This pure-perovskite approach leverages the material’s inherent advantages: perovskites can be printed in thin, flexible layers using low-temperature processes, potentially cutting production costs to under two United States dollars per watt—half the cost of silicon cells. The company’s 2025 progress was fueled by a key material innovation: a proprietary “cross-linked perovskite crystal” structure that reduces defects in the film, boosting both efficiency and stability. In parallel with its efficiency record, SolaEon launched a 200-megawatt pilot production line in Jiangsu, China, in March 2025—constructed in just four months—and began shipping small-batch modules to European residential solar installers for field testing. “Silicon has dominated for 40 years, but perovskites let us rethink solar from the ground up,” said SolaEon CEO Dr. Elena Müller, adding that the pilot line’s yield rate (the percentage of usable cells produced) had already reached 82%, a key metric for commercial viability.

Both companies have addressed perovskite’s historic Achilles’ heel: long-term stability. Early perovskite cells often degraded within weeks when exposed to moisture, heat, or UV light, but 2025’s breakthroughs include game-changing protective technologies. LONGi’s tandem cell uses a dual-layer encapsulation: a hydrophobic polymer film to block moisture and a UV-absorbing coating that prevents perovskite oxidation. Accelerated aging tests showed the cell retained 90% of its efficiency after 1,000 hours of continuous exposure to 85°C heat and 85% humidity—conditions far harsher than typical outdoor environments. SolaEon, meanwhile, integrated its cross-linked perovskite crystals with a transparent conductive oxide (TCO) layer that acts as a barrier to environmental damage; its cells maintained 88% efficiency after 800 hours of the same stress test, meeting the IEC’s 25-year lifespan requirement for commercial solar modules.

The race between SolaEon and LONGi carries massive implications for the global energy transition. The International Energy Agency (IEA) projects that solar will need to supply 30% of global electricity by 2030 to meet net-zero goals—up from 6% in 2023—and perovskite tandems are seen as critical to achieving this. Analysts at BloombergNEF estimate that if 30% efficiency cells reach mass production by 2028, solar power costs could drop by 22%, making it cheaper than coal in even the most energy-intensive economies. Governments are already doubling down on support: the European Union’s 2025 Green Deal Industrial Plan allocated five hundred million United States dollars to perovskite research, while China’s 14th Five-Year Plan for New Energy includes tax incentives for manufacturers scaling tandem cell production.

As the year progresses, the competition shows no signs of slowing. LONGi has announced plans to expand its pilot line to 1 gigawatt by early 2026 and launch commercial sales by 2027, targeting utility-scale solar farms first. SolaEon, meanwhile, is partnering with French energy firm TotalEnergies to develop flexible perovskite modules for rooftop installations and portable solar generators, with commercialization slated for 2026. For a world racing to cut carbon emissions, these 2025 breakthroughs are more than technical wins—they’re proof that solar energy can evolve faster than ever before. “We’re not just building better solar cells,” Dr. Li said at SNEC. “We’re building a future where clean energy is cheaper, more accessible, and impossible to ignore.”

(Writer:Galli)